From textile waste to a recycled veneer

The veneer is made of textile waste, such as old denim, army clothing, suits and white denim. But also from biobased fibres, such as flax, hemp, and jute coffee bags. The fibres are first shredded into small pieces and then carded into felt. The felt is eventually pressed with a biodegradable binder made of potato - or corn starch into a hard veneer. This veneer lends itself perfectly to new high-end products.

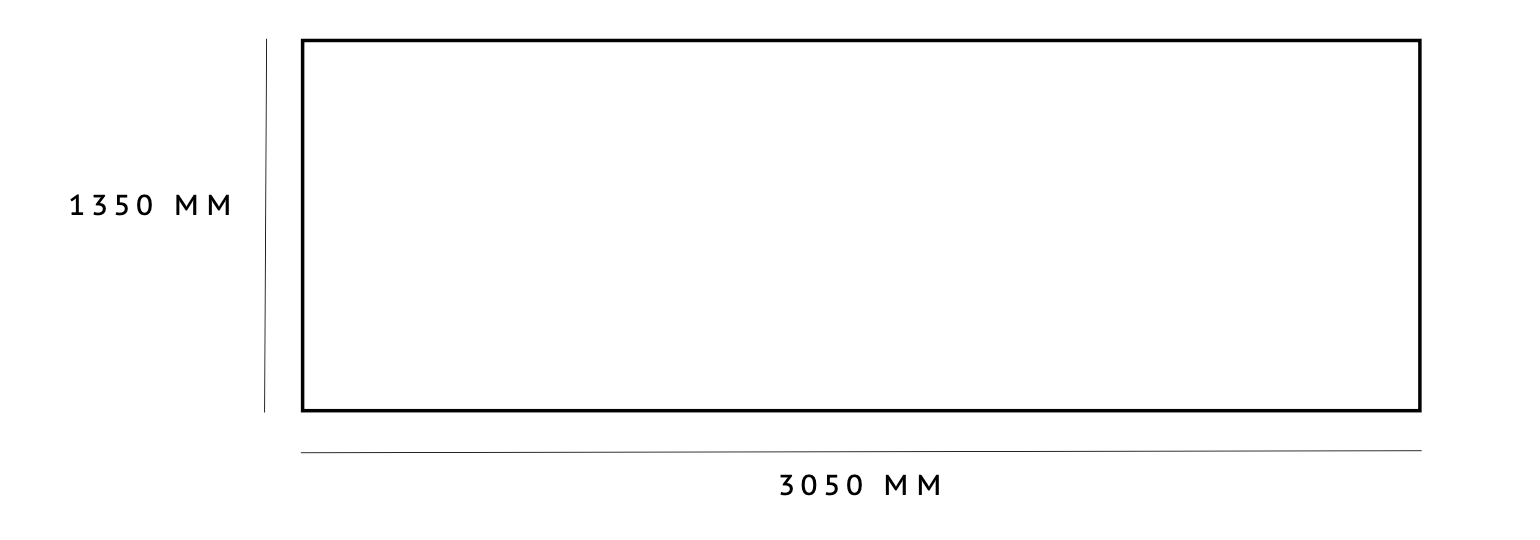

.Size

Rezign® Veneer is available in a gross size of 3050x1350 mm with a thickness of 0.8 mm.

The nett size of the veneer is 3050x1300 mm.

Different recycled textiles result in multiple colours of Rezign® Veneer. However, please note that since it is all recycled, different batches of clothing or biobased fibres may have a different colour outcomes. Therefore, the veneer is unique and one-of-a-kind.

.Signature collection

Suits

White Denim

Recycled bank suits in black - greyish colour.

Only white coloured jeans are selected for

this veneer.

.Master collection

Recycled jute coffee bags from the coffee and chocolate industry.

.Nature collection

A 100% biobased and renewable fiber grown locally.

Flax

Made from the clothing of the Dutch army and recycled after their good work for world safety.

Denim

Recycled jeans from post consumer resources or fashion brands

Jute Coffeebags

Army

-

For the cleaning of the surfaces, use light-moist cotton or microfibre cloth. Then carefully wipe off and rub with a clean dry cotton cloth. Or make use of a feather whisper against dust-gathering. To clean a specific stain we recommend intervening immediately and using an organic solvent (ex. trichloroethylene). Do not use abrasive sponges as they may damage the product’s surface. Avoid using acidic products, solvents, and products containing ammonia. Periodic and correct maintenance allows the product to keep its original aspect and lengthen the duration of its performance.

Only recommended for indoor use.

-

The veneer is made of recycled textiles and biological fibres in combination with a biodegradable matrix. It is splash-proof, however, it is not water-resistant.

-

The Rezign® Veneer has a gross size of 3050x1000 mm with a thickness of 1 - 1.3 mm. The nett dimension is 3000x970 mm.

Please see the Rezign® Technical Sheet for more information

-

The veneer can be glued to various wood panels. For sustainable glues, we recommend Circuwall Glue, Niaga Glue. But Standard D3 and spray glue are possible as well.

For the panels we suggest, for example, Greengridz, Ecor, MDF, Chipwood etcetera. This method is perfect for panels, doors, tabletops or any other products with a solid look. For the edge banding, we recommend using a standard edge banding machine.

Please note: when pressing in order to attach the veneer to the panel, please be aware that the heat must not be higher than 80°C.

-

There are several ways to process the Rezign® Veneer. It is recommended to test and learn different processing techniques before designing.

For more information regarding editing the veneer, we recommend reading the Rezign® Technical sheet.

-

The veneer will be shipped with the gross size as rolls in a box. Six veneers fit one box. Horizontal transport is also possible on request.